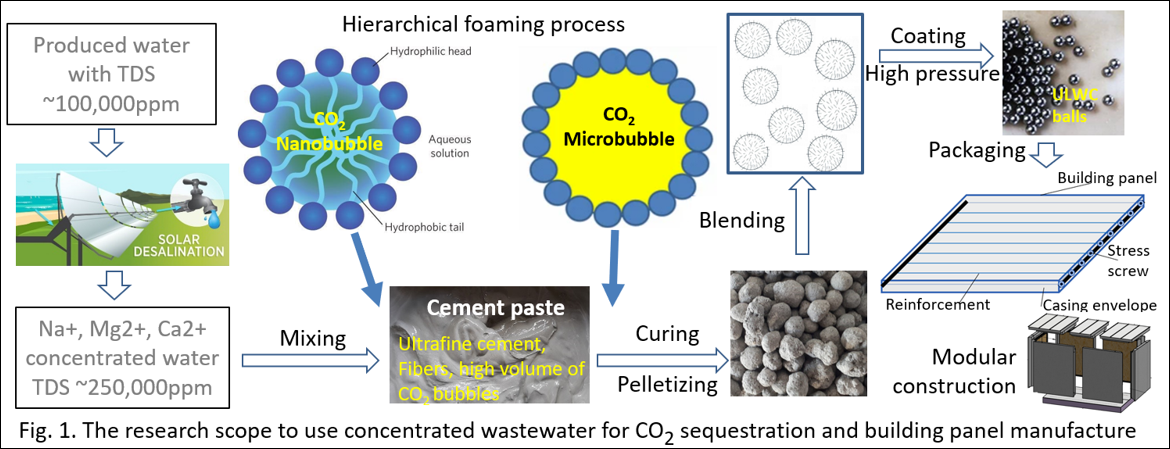

Manufacturing of Ultralightweight Concrete Panels for Carbon Negative Buildings

This project uses produced water from the oil and gas (O&G) industry and concentrates the mineral (Na+, Ca2+, and Mg2+) content to a desirable level by multistage flash (MSF) hypersaline desalination, and mixes it with cement paste, fibers, and supplementary cementitious materials. Afterward, through a proprietary CO2 foaming process, carbon is injected and sequestered into the mix. Subsequent hydration and carbonation reactions will be accelerated by a CO2-specific surface area of >100m2/g, which will yield a highly porous microstructure for a cellular lattice-based ultralightweight composite (ULWC). The paste can be cured and pelletized into small grains with high porosity (~90%), or directly injected into molds to manufacture ULWC blocks and panels.